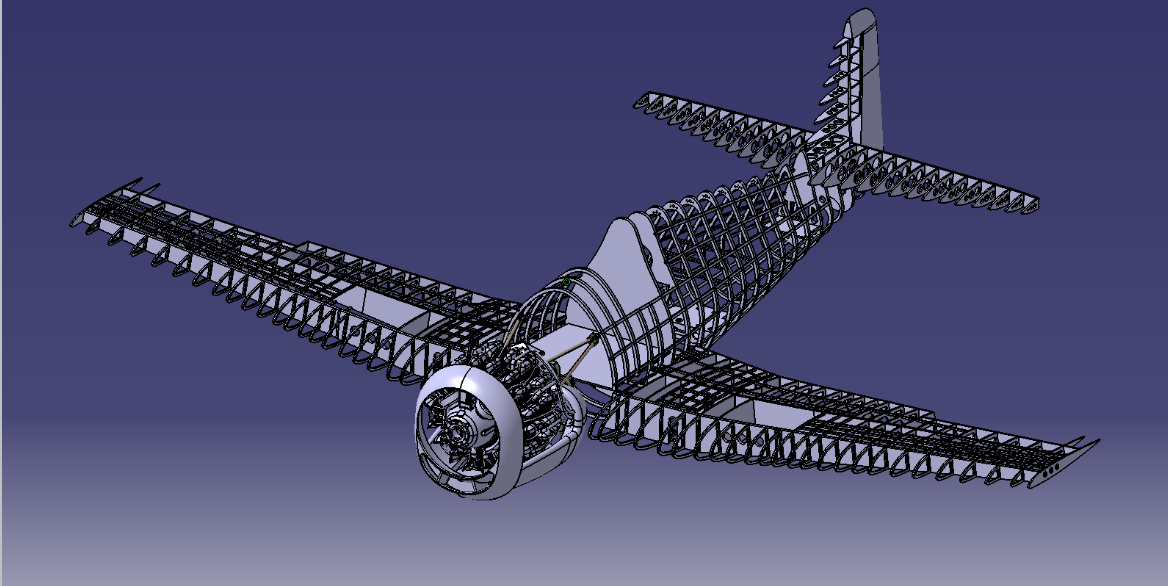

Designing aerospace components isn’t just about drawing shapes on a screen. It’s about building systems that defy gravity, withstand brutal stresses, and comply with some of the strictest regulations in engineering. Your CAD software isn’t just a tool—it’s the foundation of your product development pipeline.

In this guide, we’ll explore how to choose the right CAD software for aerospace product design, with a practical comparison of three heavyweights: SolidWorks, CATIA, and Siemens NX.

Why CAD Software Choice Matters in Aerospace

Aerospace design demands:

- Precision 3D modeling for complex geometries

- Advanced surface modeling for aerodynamics

- Seamless integration with simulation tools (FEA, CFD)

- Support for large assemblies and tight tolerances

- Configuration control and compliance documentation

The wrong CAD tool can bottleneck your workflow, introduce costly errors, or limit your ability to simulate real-world conditions. Let’s break down what each option offers.

SolidWorks: Accessible Powerhouse for Mid-Tier Aerospace Projects

Best for: Small to mid-sized teams, prototyping, general mechanical design

Strengths:

-

- Intuitive user interface and short learning curve

- Strong part and assembly modeling tools

- Good for bracketry, housings, mechanical linkages

- Integrated Simulation (FEA-lite) tools available

- Large third-party plugin ecosystem

Limitations:

-

- Less robust surfacing tools

- Assembly performance lags with large aerospace assemblies

- Lacks native high-end simulation integration (requires external tools)

- Not ideal for highly regulated environments (compared to CATIA/NX)

Bottom Line: SolidWorks gets you off the ground quickly, but may struggle at cruising altitude in advanced aerospace workflows.

CATIA: The Aerospace Industry Standard

Best for: OEMs, tier-1 suppliers, advanced surfacing and regulatory-heavy projects

Strengths:

-

- Best-in-class surface modeling (Class A surfacing)

- Widely adopted in aerospace OEMs (Airbus, Boeing, Dassault, etc.)

- Powerful configuration and BOM management

- Integrated with ENOVIA PLM for compliance and documentation

Limitations:

-

- Steep learning curve

- Expensive licensing

- Legacy UI in some modules

- Slower workflows unless heavily customized

Bottom Line: CATIA is the old guard—powerful, respected, and widely adopted. But it’s not always the most efficient option for modern teams.

Siemens NX: Streamlined Power for Integrated Simulation Workflows

Best for: Advanced product development, simulation-driven design, multidisciplinary teams

Strengths:

-

- Excellent integration of CAD, FEA, and CFD in one environment

- Strong parametric and direct modeling tools

- Superior workflow efficiency (especially in analysis-driven design)

- High performance for large assemblies and complex geometries

- Ideal for structural + aerodynamic simulations

Limitations:

-

- Still has a learning curve (though better than CATIA)

- Cost may be high for small firms (but ROI is strong for mid-large teams)

Bottom Line: If you’re doing structural or aerodynamic design and want a streamlined workflow from modeling to analysis, Siemens NX is a strong contender—and for many modern teams, the smartest choice.

Practical Comparison Table

| Feature | SolidWorks | CATIA | Siemens NX |

| Surface Modeling | Moderate | Excellent | Very Good |

| Assembly Performance | Moderate | High | Very High |

| Simulation Integration | Basic | External | Native, Strong |

| Workflow Efficiency | High | Moderate | Very High |

| Cost | Moderate | High | High |

| Ideal For | General Mech Design | OEM/Tier-1 Aerospace | Analysis-Driven Design |

Wajihuddin’s Final Thoughts (From Voltron Future)

At Voltron Future, we’ve worked extensively with both CATIA and Siemens NX. While CATIA’s surfacing tools are legendary, we lean toward Siemens NX for aerospace product development thanks to its unmatched workflow integration and simulation readiness.

Whether you’re optimizing airframe structures or running FEA on aerodynamic surfaces, having your modeling and simulation tools in a unified environment saves time, reduces translation errors, and boosts design quality.

The best CAD software is the one that empowers your workflow, not clutters it.

Ready to Take Off?

Want help choosing the right tools, optimizing your aerospace product workflow, or outsourcing high-end CAD and simulation work? Let’s talk — we’re Voltron Future, and this is what we do.